ما هي المضخة الهيدروليكية؟ ما مبدأ عملها؟ ما بنيتها؟ كيف تُصنّف؟

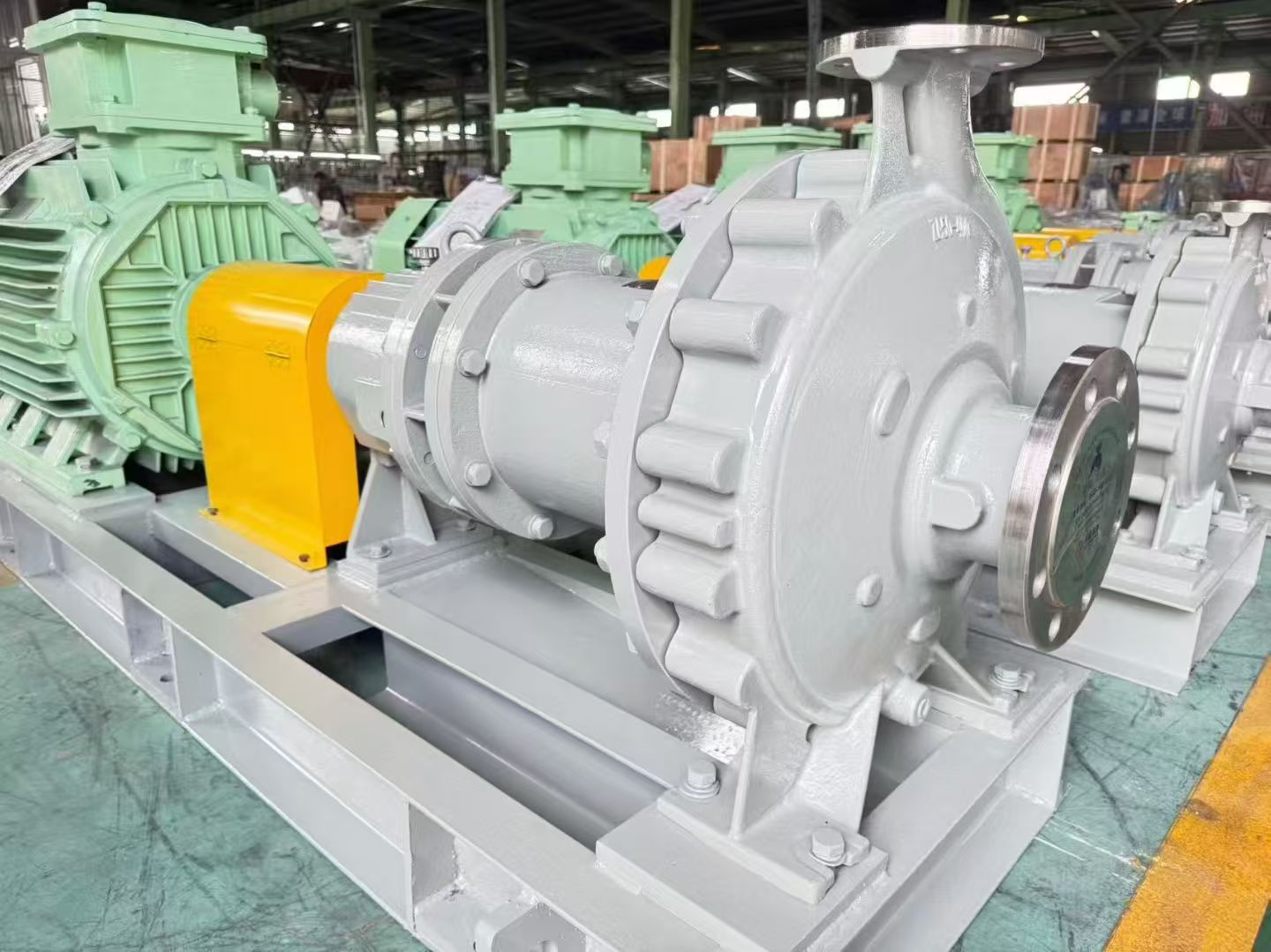

اليوم، شركة آنهوي شنغشي داتانغ للمعدات الكيميائية المحدودة هنا لتقديم تفسير للجميع. المضخة الهيدروليكية هي مُكوّن الطاقة في النظام الهيدروليكي. تُدار بواسطة محرك أو موتور، وتسحب الزيت من... في الخزان الهيدروليكي، يُشكّل الزيت المضغوط، ويُفرّغه إلى المُشغّلات. تُصنّف المضخات الهيدروليكية حسب هيكلها إلى مضخات تروس، ومضخات مكبس، ومضخات ريشية، ومضخات دوارة. مضخات لولبية .

I. مبدأ عمل المضخات الهيدروليكية

مبدأ عمل المضخة الهيدروليكية هو أن الحركة تُحدث تغيرات في حجم حجرة المضخة، مما يؤدي إلى ضغط السائل وتزويده بطاقة ضغط. الشرط الأساسي هو أن يكون حجرة المضخة مُحكمة الإغلاق لتغيير الحجم.

المضخة الهيدروليكية هي نوع من المضخات التي توفر سائلًا مضغوطًا للنقل الهيدروليكي. وظيفتها هي تحويل الطاقة الميكانيكية لمصدر طاقة (مثل محرك كهربائي أو محرك احتراق داخلي) إلى طاقة ضغط سائل. يتم تدوير كامتها بواسطة محرك كهربائي. عندما يدفع الكامة المكبس لأعلى، ينخفض الحجم المختوم الذي يشكله المكبس والأسطوانة، مما يجبر الزيت على الخروج من الحجم المختوم وتفريغه عبر صمام عدم الرجوع إلى حيث يكون هناك حاجة إليه. عندما يدور الكامة إلى الجزء الهابط من المنحنى، يدفع الزنبرك المكبس لأسفل، مما يخلق فراغًا معينًا. يدخل الزيت الموجود في الخزان الحجم المختوم تحت الضغط الجوي. مع تحريك الكامة للمكبس لأعلى ولأسفل باستمرار، ينخفض الحجم المختوم ويزداد بشكل دوري، مما يسمح للمضخة بسحب الزيت وتفريغه باستمرار.

تؤثر عوامل عديدة على عمر خدمة المضخة الهيدروليكية. فبالإضافة إلى تصميم المضخة وتصنيعها، يلعب اختيار المكونات المتعلقة باستخدامها (مثل الوصلات، وفلاتر الزيت، وغيرها) وطريقة تشغيلها أثناء التجارب التشغيلية دورًا هامًا.

II. مكونات المضخة الهيدروليكية

تتكون المضخة الهيدروليكية من ثلاثة أجزاء: الوصلة، والخزان الهيدروليكي، وفلتر الزيت.

1. الاقتران:

لا يتحمل عمود إدارة المضخة الهيدروليكية القوى الشعاعية أو المحورية. لذلك، لا يُسمح بتركيب بكرات أو تروس أو أسنان مسننة مباشرةً على طرف العمود. عادةً، تُستخدم وصلة لربط عمود الإدارة بعمود نقل الحركة. إذا تجاوزت الوصلة المحورية بين المضخة والوصلة المعيار، لأسباب تصنيعية، وكان هناك انحراف في التجميع، تزداد قوة الطرد المركزي مع زيادة سرعة المضخة، مما يُشوّه الوصلة. ويؤدي هذا التشوه بدوره إلى زيادة قوة الطرد المركزي، مما يُؤدي إلى حلقة مفرغة. ينتج عن ذلك اهتزاز وضوضاء، مما يؤثر على عمر خدمة المضخة. تشمل العوامل المؤثرة الأخرى عدم إحكام ربط دبابيس الوصلة في الوقت المناسب وعدم استبدال الحلقات المطاطية البالية في الوقت المناسب.

2. الخزان الهيدروليكي:

الوظائف الرئيسية للخزان الهيدروليكي في النظام الهيدروليكي هي تخزين الزيت، وتبديد الحرارة، وفصل الهواء عن الزيت، وإزالة الرغوة. عند اختيار الخزان، يجب أولاً مراعاة سعته. عادةً، تتطلب المعدات المتحركة معدل تدفق أعلى من الحد الأقصى للمضخة بمرتين إلى ثلاث مرات، بينما تتطلب المعدات الثابتة 3 إلى 4 مرات. بعد ذلك، يجب مراعاة مستوى زيت الخزان. عند تمديد جميع أسطوانات النظام الهيدروليكية، يجب ألا ينخفض مستوى الزيت في الخزان عن الحد الأدنى. عند انكماش الأسطوانات، يجب ألا يتجاوز مستوى الزيت الحد الأقصى. وأخيرًا، يجب مراعاة هيكل الخزان. لا تُستخدم ألواح الفصل في الخزانات التقليدية لترسيب الأوساخ. يجب تركيب لوح فصل رأسي على طول المحور الطولي للخزان. يجب ترك مسافة بين أحد طرفي لوح الفصل ولوح نهاية الخزان لربط الفراغات على جانبيه. يجب ترتيب منافذ دخول وخروج المضخة الهيدروليكية على الجانب المنفصل من لوح الفصل، مع ضمان أقصى مسافة بين منفذي دخول وعودة الزيت. وهذا يسمح للخزان الهيدروليكي بلعب دور أكبر في تبديد الحرارة.

3. فلتر الزيت:

بشكل عام، يكون تأثير الملوثات التي يقل حجم جسيماتها عن 10 ميكرومتر ضئيلاً على المضخة، بينما تؤثر الملوثات التي يزيد حجم جسيماتها عن 10 ميكرومتر، وخاصةً التي يزيد حجمها عن 40 ميكرومتر، بشكل كبير على عمر خدمة المضخة. يمكن لجزيئات الملوثات الصلبة في الزيت الهيدروليكي أن تُسرّع بسهولة تآكل الأجزاء المتحركة النسبية داخل المضخة. لذلك، يجب تركيب فلتر زيت لتقليل درجة تلوث الزيت. تتراوح دقة الترشيح المطلوبة بين 10 و15 ميكرومتر لمضخات المكبس المحوري، و25 ميكرومتر لمضخات الريش، و40 ميكرومتر لمضخات التروس. هذا يُمكّن من التحكم في تآكل المضخة الناتج عن التلوث ضمن الحدود المقبولة. حاليًا، يزداد استخدام فلاتر الزيت عالية الدقة، مما يُطيل عمر خدمة المضخات الهيدروليكية بشكل كبير.

ثالثًا. تصنيف المضخات الهيدروليكية

أنواع المضخات الهيدروليكية الشائعة:

١. بناءً على إمكانية تعديل معدل التدفق، تُصنف المضخات إلى مضخات متغيرة ومضخات ثابتة. تُسمى المضخات التي يُمكن تعديل معدل تدفقها حسب الحاجة بالمضخات المتغيرة، بينما تُسمى المضخات التي لا يُمكن تعديل معدل تدفقها بالمضخات الثابتة.

2. بناءً على الهيكل المستخدم بشكل شائع في الأنظمة الهيدروليكية، يتم تصنيفها إلى ثلاثة أنواع: مضخات التروس، ومضخات الريشة، ومضخات المكبس.

أ. مضخة التروس: تتميز بحجمها الصغير، وبنيتها البسيطة نسبيًا، ومتطلباتها الأقل صرامةً لنظافة الزيت، وكلفتها المنخفضة نسبيًا. ومع ذلك، يتعرض عمود المضخة لقوى غير متوازنة، مما يؤدي إلى تآكل شديد وتسرب كبير.

ب. مضخة الريشة: تنقسم إلى مضخات ريشة مزدوجة المفعول ومضخات ريشة أحادية المفعول. تتميز هذه المضخات بتدفق منتظم، وتشغيل سلس، وضوضاء منخفضة، وضغط تشغيل أعلى، وكفاءة حجمية أعلى مقارنةً بالمضخات الترسية. ومع ذلك، فإن بنيتها أكثر تعقيدًا من بنية المضخات الترسية.

ج. مضخة المكبس: تتميز بكفاءة حجمية عالية، وتسرب منخفض، وقادرة على العمل تحت ضغط عالٍ، وتُستخدم غالبًا في الأنظمة الهيدروليكية عالية القدرة. ومع ذلك، تتميز بتركيب معقد، وتتطلب مواد عالية الجودة ودقة تصنيع عالية، كما أنها باهظة الثمن، وتتطلب نظافة عالية للزيت.

عمومًا، تُستخدم مضخات المكبس فقط عندما لا تفي مضخات التروس والمضخات الريشية بالمتطلبات. هناك أشكال أخرى من المضخات الهيدروليكية، مثل: مضخات لولبية ، ولكنها أقل استخدامًا مقارنة بالأنواع الثلاثة المذكورة أعلاه.