طرق فعالة لتعزيز كفاءة وموثوقية المضخات العمودية

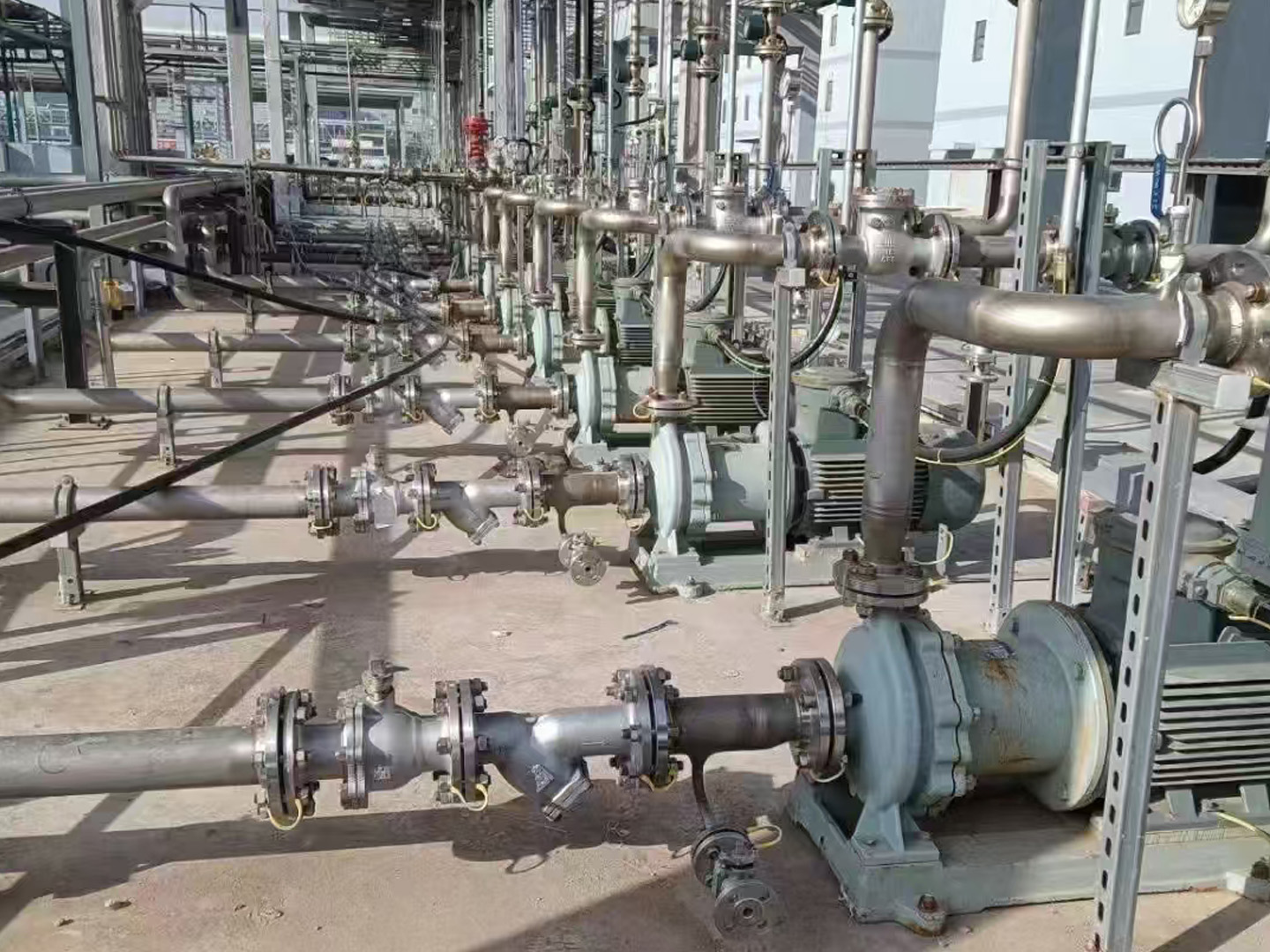

انهوى شينغشي داتانغ سأقدم لك الآن شرحًا علميًا مبسطًا. الماء موردٌ مهم، يُستخدم عادةً في عمليات التبريد الصناعي وغيرها من التطبيقات غير المعتمدة على API. بفضل تصميمها الموثوق، تُستخدم المضخات العمودية على نطاق واسع. وهي معدات أساسية في صناعات المياه والبتروكيماويات وتوليد الطاقة لنقل كميات كبيرة من المياه. ومن خلال تحسين أداء وكفاءة هذه المضخات الحيوية، يُمكن خفض تكاليف التشغيل والصيانة بشكل كبير.

مطابقة الأداء

غالبًا ما تُغفل المضخات العمودية أثناء الصيانة الدورية. تصميمها الموثوق يجعلها نادرة الاهتمام في الظروف العادية. مع ذلك، مع مرور الوقت، قد يؤدي التآكل والتلف في مكوناتها المختلفة إلى انخفاض كفاءتها تدريجيًا، وبدون صيانة مناسبة، قد يتسارع هذا الانخفاض.

يُعد الحفاظ على ظروف التصميم الهيدروليكي للتطبيق أمرًا بالغ الأهمية لموثوقية المضخة وأدائها. يُعزز التشغيل ضمن نطاق التفاوت المسموح به على جانبي نقطة أفضل كفاءة (BEP) للمضخة مقاومة الأعطال. أما التشغيل خارج هذا النطاق فقد يؤدي إلى زيادة الاهتزاز، وانخفاض عمر المحمل، وتقصير عمر السدادة الميكانيكية، وزيادة الأعطال العشوائية، وانخفاض عام في عمر المضخة.

التكيف مع المتطلبات المتغيرة

من السيناريوهات الشائعة أن تكون المضخة قيد الاستخدام لسنوات عديدة، ولكن خلال هذه الفترة، تتغير ظروف الاستخدام. على سبيل المثال، غالبًا ما تُخفض معدلات التدفق باستخدام صمامات التحكم أسفل المضخة. هذا يعني أن المضخة قد تعمل بأقل من 50% من معدل التدفق المُصمم لها، مما يزيد من تكاليف التشغيل ويؤثر على عمر صمام التحكم. والأسوأ من ذلك، أن أي انخفاض في أداء المضخة قد لا يُلاحظ؛ وقد يلجأ المشغلون ببساطة إلى فتح صمام التحكم قليلًا للتعويض.

الحل هو تعديل المعلمات الهيدروليكية للمضخة لتتوافق بشكل أفضل مع التطبيق المُعدَّل. هذا يسمح لصمام التحكم بأداء الغرض المُخصص له بدلاً من العمل كمُقيِّد للتدفق، ويُمكّن المضخة من العمل بالقرب من أقصى كفاءة تشغيل لها. مع ذلك، فإن إجراء تغيير واحد، مثل تعديل المروحة، قد يُحقق النتيجة المرجوة، ولكنه قد يُثير أيضًا تحديات أخرى تتطلب تحليلًا دقيقًا.

ضمان الحد الأدنى من التدفق

هناك مشكلة شائعة أخرى تتعلق بالأنظمة المصممة للحفاظ على أدنى معدل تدفق عند مدخل المضخة. تُستخدم صمامات إعادة التدوير لضمان أدنى تدفق مستقر ومستمر، مما يحمي المضخة من التلف الناتج عن انخفاض التدفق. ومع ذلك، فإن جميع المياه المتدفقة عبر هذه الصمامات تُمثل طاقة مهدرة. ومما يزيد من تفاقم هذه المشكلة، أن هذه الأنظمة غالبًا ما تكون غير مُصممة بشكل صحيح. مع مرور الوقت، قد تؤدي هذه المشكلة البسيطة إلى عواقب وخيمة، مثل تلف التجويف في الدافع.

قد يستبدل المشغلون صمامات إعادة التدوير، لكنهم يفتقرون إلى المعرفة أو القدرة على ضمان التركيب والإعداد المناسبين. من هذه النقطة فصاعدًا، قد تتعرض المضخة، المصممة للحماية، لتآكل متسارع.

مكونات جديدة

من الواضح أن مكونات المضخة ستتآكل بعد سنوات من الاستخدام، وستحتاج في النهاية إلى استبدالها. في هذه المرحلة، من المهم فهم الفرق بين الأجزاء المجددة والأجزاء المُعاد تصميمها، بالإضافة إلى كيفية تمكين التطورات في المواد وتحليل التصميم وعمليات التصنيع للمكونات الجديدة من تقديم أداء وموثوقية أعلى.

إن مجرد تجديد الأجزاء الحالية قد يؤدي إلى انخفاض الكفاءة، وتلف مبكر للمحامل والسدادات، وزيادة الاهتزاز. قد تنشأ هذه المشاكل نتيجةً لضعف هندسة التصميم، مما يؤدي إلى عدم تحقيق أبعاد جديدة، وتشطيبات سطحية دون المستوى، وخلوص غير مثالي.

باستخدام قطع غيار أصلية كنقطة انطلاق وتطبيق المعايير الهندسية الحالية لتحسين التصميم، يُمكن إنشاء مكونات جديدة بنماذج هيدروليكية مُحسّنة. كما يُمكن إجراء تعديلات طفيفة تتضمن تصميمات مُحسّنة للمحامل والأختام كجزء من المشروع، مما يُطيل عمر الخدمة ويُقلل تكاليف الصيانة.

المحامل

تصميم المضخات العمودية تعتمد المضخة على تصميم متين للمحامل لضمان أداء مستدام. لذلك، من الضروري فهم الخيارات المتاحة من حيث المواد وأنظمة التزييت بدقة لضمان تركيب النظام الأنسب. بمواءمة تصميم المحامل مع التطبيق، يمكن إطالة عمر المضخة وتقليل تكاليف الصيانة.

في كثير من الحالات، يُحدد تآكل نظام المحامل جدول صيانة المضخة، لذا فإن الخيارات المُتخذة في هذه المرحلة لها آثار مستقبلية هامة. يُمكن أن يُساعد استخدام المواد المُركبة في منع التشغيل الجاف وتوفير مقاومة أفضل للتآكل والصدأ.

لكل تطبيق تصميم مثالي للمحامل، بما في ذلك تقنية التزييت المستخدمة. بعض الحالات تكون أكثر ملاءمة لأنظمة أغطية المحامل، بينما يكون أداء المحامل المُشحمة بالمنتج أفضل في حالات أخرى. من المهم فهم مزايا كل نظام والتعاون مع خبراء تصميم المضخات لاختيار الحل الأنسب.

أنظمة الختم

عند التعامل مع المحامل، يجب أيضًا مراعاة نظام الختم. فرغم أن التغليف تصميم تقليدي، إلا أنه لا يزال له مكانة في أنظمة الختم الحديثة. فإذا تمت صيانته بشكل صحيح، يُمكنه أن يُكمّل المحامل بتوفير دعم إضافي والمساعدة في تخفيف الاهتزازات.

وفي الوقت نفسه، تتمتع الأختام الميكانيكية بمكانتها اعتمادًا على التطبيق، ويمكن للتقنيات المبتكرة مثل Liqui-Seal من Sulzer أن تقدم مزايا كبيرة، وخاصة للمضخات المبردة بالماء.

بعد الانتهاء من أعمال الصيانة، يُعدّ إعادة تركيب المضخة بشكل صحيح أمرًا بالغ الأهمية لضمان استمرارية موثوقيتها. تُعد المحاذاة الصحيحة للمضخات الرأسية من أهم جوانب أي عملية صيانة، وينطبق ذلك على كلٍّ من لوحة القاعدة والمحامل الوسيطة. يجب تنفيذ إجراءات التجميع والتركيب بعناية فائقة. حتى أدنى خطأ في المحاذاة على طول المضخة قد يؤدي إلى انخفاض كبير في عمرها الافتراضي.